Now for the testing of the forge. Ad Cylinders case forgings many other parts In a variety of materials.

After doing a lot of research and collecting up materials I have finally built one.

. Should the airflow pipe come in from the side instead of the bottom. You could have a side blast forge that has a side draft chimney too I suppose. The biggest thing to me is insulation and where your forge doors are with a side blast I found that having a door close from the opposite side works best.

Reliability when it matters most. The side blast forge can be fabricated by any blacksmith with the tools to cut and weld steel plate and pipe. Should the airflow pipe come in from the side instead of the bottom.

Not pictured but also included is a third hand to help with long pieces. All a forge is is a container to hold the coals and an air source that can be controlled. I dont give out prices by email.

Side Blast Forge Design. Seems fine to work no real noticeable difference except with the side blast every now and then the thing would erupt if you left the air up too high when the coke was spent in the pot andor the sand coke clinker waste pit was getting dried out at the end of a day. The frame was cleaned to bear metal and painted with rust converter.

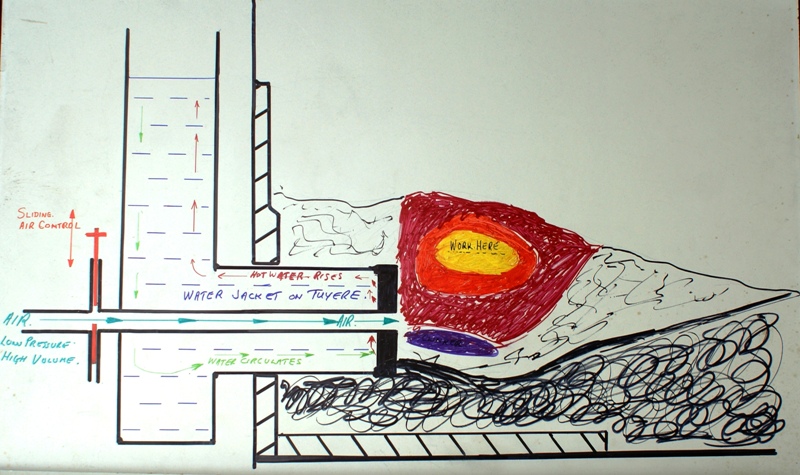

The Bosh is connected to the Tuyere with a bottom cold water tube and the top is connected to the hot water tube. Here it is in all. This text is only meant to show that a good ready-made firepot is the best option if the smith chooses a bottom air blast.

Opinions on first forge design idea. The cheapest type of forge is a coal forge. Its flawless design allows for superior handling.

Dies are properly aligned. Tai Goo whose videos I also recommend has a different kind of washtub forge with a side blast and the firepot made of straight wood ashes that he can reshape as needed. This is my first rough design for a forge.

The simplest form would be a shallow square hole in the ground about 6 inches deep and 10 inches on a side with a pipe running under ground into the side of the hole about 2 inches above the bottom. Opinions on first forge design idea. Side blast forge design To apply just adhere on the nails we like to maintain them at the base of our nail beds and set with very clear topcoat.

At the front of the forge I included a tool rack made from 14 x 2 flat from which tongs poker or whatever can be hung. This a Side Blast Forge built in the UK by Mike Judd of Greystone Forge. Oct 30 2018 - Side blast forge.

Posted by 4 years ago. Text or emails without contact phone number will not be replied to. Most of the.

316 Hot rolled plate material was used in the building of this traditionally British Side Blast forge however they have been built out. I now use a bottom blast forge made from a cast iron block. How to Use The Blast Forge The Blast Forge is best used when facing heavily armored Machines as you can use the Explosive Bolts to weaken the armor then switch over to the AdvancedPiercing Bolts to deal large amounts of damage to the exposed areas.

Some requests have been for a smaller forge furnace mini forge special chimney designs gas forge and more. I am using used antifreeze as a coolant for two reasons 1 shouldnt rust the Bosh. This does NOT preclude the use of the sideblast tuyere used by many smiths.

My forge has a burner in the side at a 90 degree angle and works fine. It shows the basic principles of a Water cooled Side Blast Forge. The swordsmith forge consists of a fuigo box bellows separated from the forge by a low wall a firepot consisting of two parallel walls to contain the fire and a charcoal reservoir where fresh charcoal is stored for use.

I have just finished building a Side Blast Forge Mark Aspery design with a Super Sucker Hood and 10 chimney. It has a new clutch bearing and new main bearings new main crank new. A good value in my opinion.

It is completly rebuilt. OK im confused. Below the air blast.

Mike Deibert adapted the design for his school in Nicaragua using barrels. Little giant power hammer. Having a burner on top also puts more back pressure on your system which can result in a flame escaping out of the back of your burner.

This was made by welding two. Is a side draft forge same as a side blast forge or is a side draft forge a forge of any sort of blast configuration that just has a chimney that draws off to the side I suppose like the pictures Ive seen of Hofis. Excelent for using charcoal fuel.

Greystone Forge can customise any forge to your requirements or build something specific tailored to your specifications. I have been wanting a side blast forge for a LONG time. An eye-catching style hasnt been less complicated.

Thanks stevefor sale is this old style 25 lb. The bottom half of the firepot area is filled with fine charcoal to provide an insulated bed for the fire and extends under the charcoal reservoir. This is my first rough design for a forge.

Building A Side Blast Forge Youtube

Agricultural Engineering In Development

My Side Blast Forge Design Solid Fuel Forges I Forge Iron

Folding Side Blast Forge Youtube

Portable Side Blast Forge Solid Fuel Forges I Forge Iron

Side Blast Forge Excelent For Using Charcoal Fuel Forging Metal Blacksmith Forge Blacksmith Projects

The 55 Forge Bottom And Side Blast Solid Fuel Forges I Forge Iron

0 comments

Post a Comment